January 29, 2006

Continued from Jan 28th...we worked on into the morning. It's now about 1:00 am.

Woops...the bolts shanks for the counterweights are just a bit too long. Here you can see the shank protruding past the washer. A definite no-no. Solution is to just use two washers instead of one.

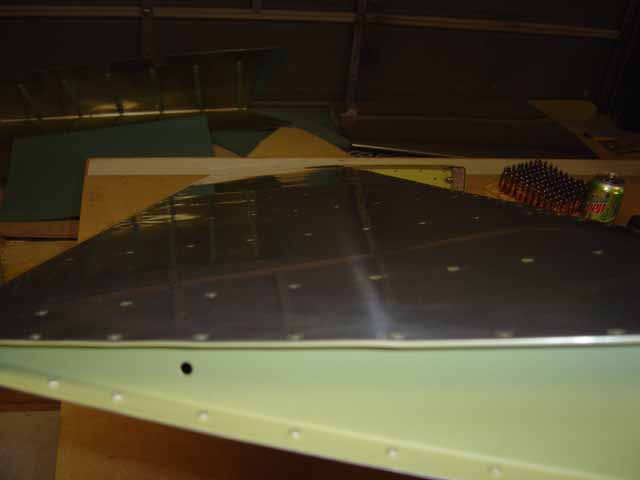

I don't have any pictures but trust me, we finished rivetting the skins. Totally nothing remarkable to report except the usual blind rivets at the trailing edges. There's just no way to rivet those. Here we are getting ready to roll the leading edges. The pipe just gets it started. There's a lot of smushing to be done with your bare hands before the leading edge is ready. There's nothing all that hard about this, but it's a bit painful on the fingers, and is just totally time consuming.

And another part is done...except for the glass, of course.

Here's a shot along the top. Nice and flat.

My leading edges are getting better, but they still have some funny kinks in them sometimes. Live and learn...the left elevator's leading edge will by better still. By the way, Vans gives a measurement from the leading edge to the front of the spar. It took me a while to figure out how to measure this because the elevator horn is in the way, but the light finally went on. First I put my little machinists ruler down along the inside of the spar and extended that line out to the inside of the wing skin. Maked it with a sharpie. Then I let my plumb bob swing over the leading edge. Measured from the mark on the skin to the plumb bob's string. Presto.

Not sure why I took this picture, but once I start, I can't stop sometimes.

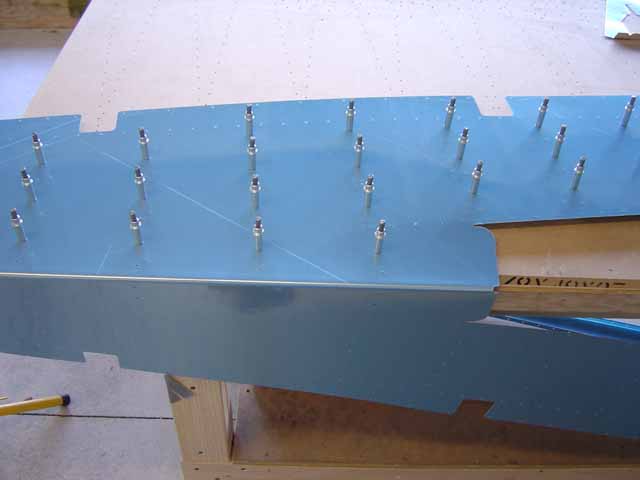

It's morning now. I drilled all the stiffeners to the skin.

The H stiffeners (the ones on the left) are easy to install backwards since there's no obvious leading or trailing edge. The easy way to get this right is to get the flange poining the same way as the other stiffeners.

I ALWAYS wear my safety glasses, now, even if I'm just drilling some stiffeners. I've had one too many pieces of metal in my eye. It's normally not all that dangerous, but with the air tools there's always an exhaust and it blows the metal all over the place. Lesson learned.