January 26, 2006

I haven't really gotten much of a response from Vans yet on this other than a general acknowledgement that yeah, they don't fit so good sometimes.

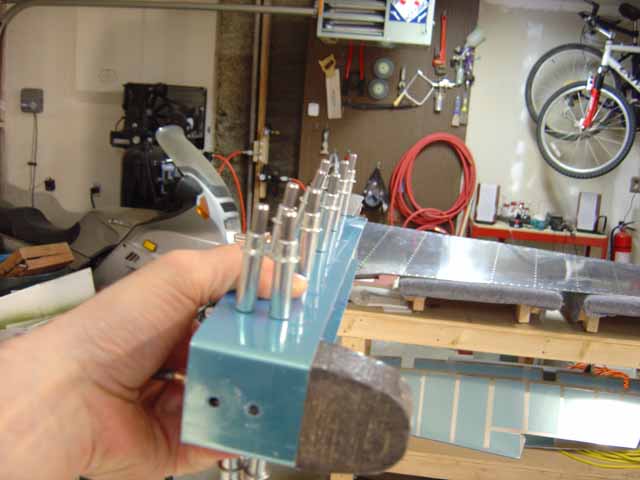

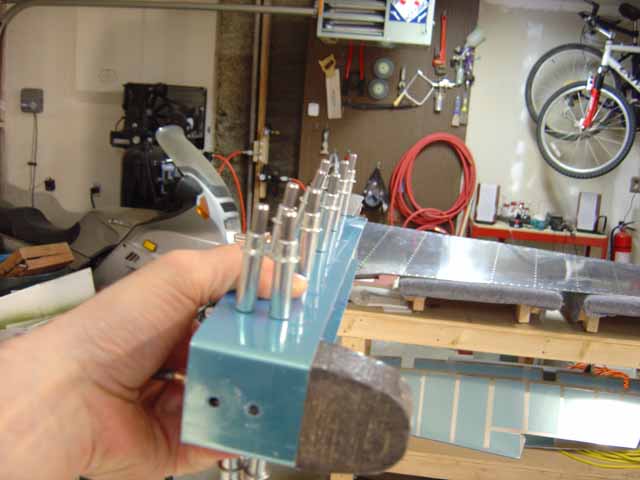

These clecos look like bad dental work....really poor fit.

Aha! What have we here? Of COURSE nothing fits. The stupid rib is bent wrong (the flange on the left is about 3/32" longer than the one on the right). I still had all the tip ribs from Tail I, so I mixed and matched until I found a couple of pairs that fit OK (I'll use the other pair for the left elevator). Believe it or not, out of the four ribs I had, two of them where bent like this.

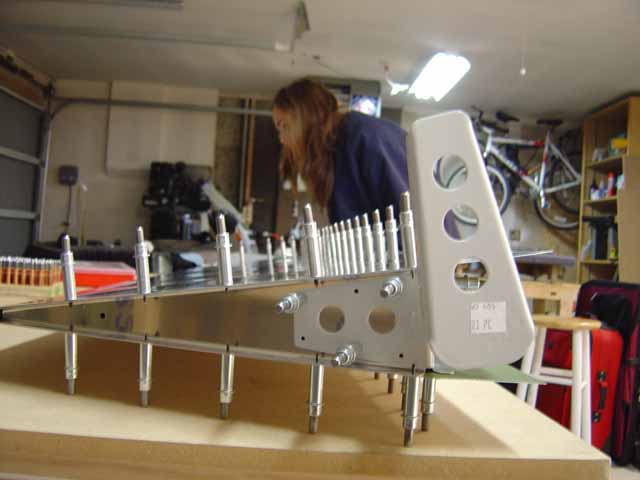

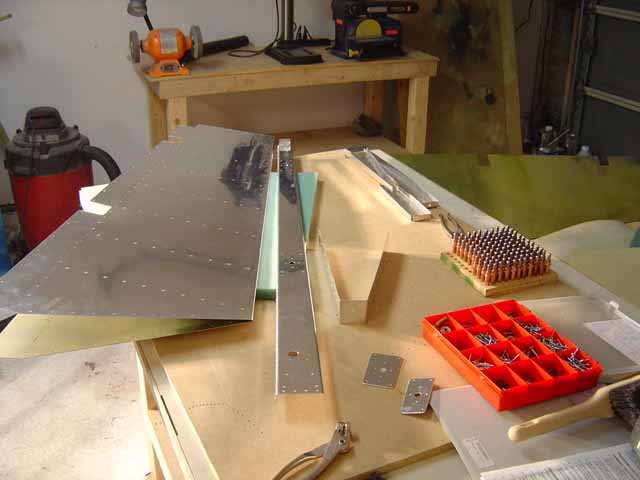

After sorting out the whole rib fiasco, I resumed clecoing everything together. Here's ellen slamming in some clecos.

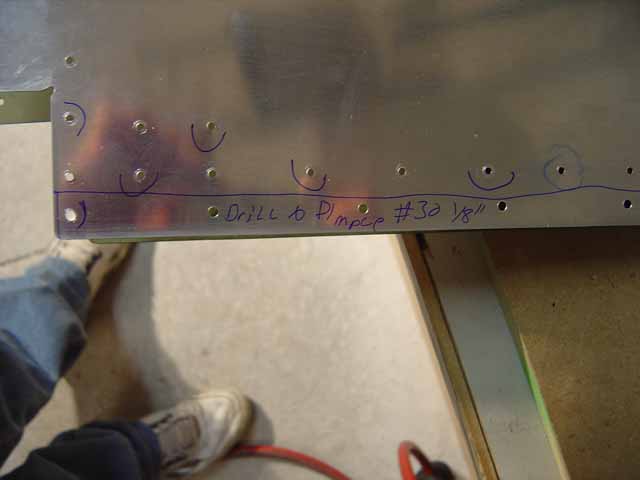

After I drilled the whole structure, I realized that as tight as the elvator is towards the trailing edge, there's no way I'll ever get a dimple die or deburring tool in there later when it comes time to fit the tips. I wrote a little note to myself to drill and dimple the tip attach holes now while I can still get something in there. These guys take CS4-4 blind rivets so they'll get drilled to #30 and dimple to 1/8. It's blind rivets so I could drill to 1/8" if I wanted to bother whiping out my other bits, but #30 works fine too. The hole just get streched out when you dimple it anyhow.

Everything's drilled. All that's left is deburring, more edge finishing, cleaning, etching, priming, and rivetting. And yes, I've switched back to AKZO. I really hate how the Tempo stuff goes on. Very tough to get a nice, light, even coat. I'll change my mind AGAIN tommorow, I'm sure...