November 11, 2005

It was at this point that I realized my screwup with the HS-710 rib and edge distance (see a few days ago for details). Nuts. Okay, fine....ordered a new HS-710, and moved on the vertical stabilizer.

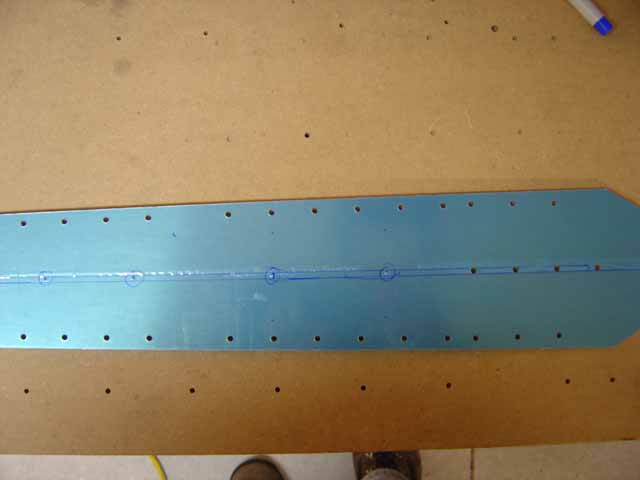

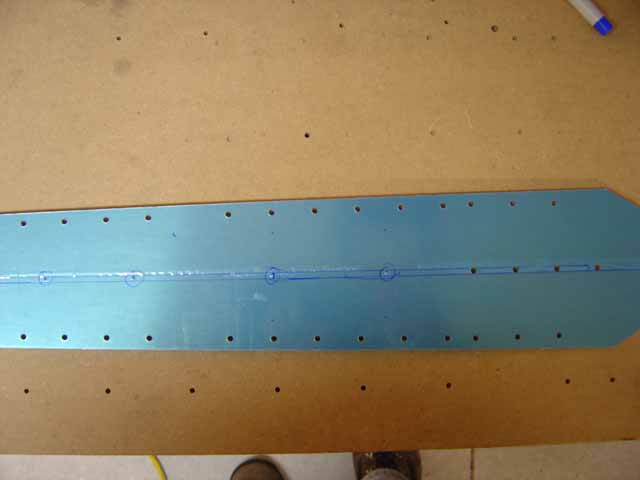

I've marked out for the lightening holes. Honestly, I REALLY didn't want to spend all day accurately measuring, and then adjusting my fly cutter to get everything JUST right. I took the 1/4 ounce penalty in weight and just made all the holes a bit smaller than they needed to be. Slapped down some measurements (accurate to 1/32" of an inch, at any rate...to me that's slapping down, I guess) and center pucnhed them. I did double check these measurements at least twice before cutting, and was sure to circle the proper locations so I wouldn't get confused by one of the prepunched holes (it COULD happen). You can barely see it in the photo, but I ran two lines from the edges of the prepunched holes. This gave me two parralel lines the length of the doubler that presumambly bracketed the center. With two lines that close together, I just measured the correct distances, and then eye-balled the center between the two lines.

Cut them suckers out. What worked best for me was to set my drill press to cut a little more than half way through. I did one whole side like this. Then I flipped it over and finished off the cuts from the back. What you end up with are these pretty cool aluminum wheels. Maybe if you smooth off the ends, you can use them as tribal ear stretching disks. Shot glass coasters? I dunno...I threw mine out.

Ellen cutting loose on the holes. Die grinder with the scotch brite wheel makes very quick work of this. I'm just way too lucky...