October 1, 2005

Using the jig from last night, I finished cutting all the stiffeners. They went pretty fast. I ended up slapping them in the jig one at a time, clamping the jig to my bench and rough cutting with a die grinder and cutting wheel, and then finished them off on the belt sander.

Here's all the stiffeners cut to size. I didn't do the final trim for length yet...I just rough cut them. I went back later and measured 1/4" from the end hole (as it says on the plans) and then ground them down to final size and shape with the disc sander. A little deburring on the scotch brite wheel and DONE. The whole process didn't take more than 15 or 20 minutes.

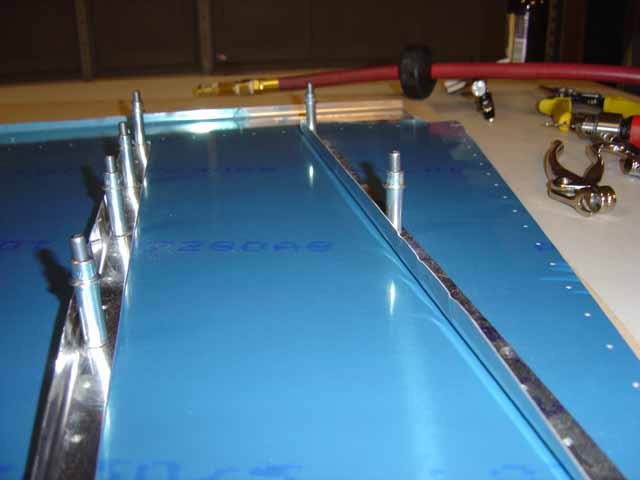

The stiffeners are match drilled to the skin (this is the left skin...I'd already done the right skin). I put some particle board down (leftover from when I built the shelves on my main workbench) so I could drill into it. I first lined up one of the holes on the stiffener with the rudder skin and drilled it, being careful to go about 1/4" into the particle board. Then I stuck a clecoe in...the clecoe goes right through, into the particle board (this is why I drilled the holes so deep). This keeps it from lifting the skin up, and also serves to clamp the skin to the particle board. Nifty. Then I lined up the other end of the stiffener and drilled and clecoed that. Finally, I drilled one in the middle and clecoed that. Now everything's lined up by 3 points and I could quickly match drill the rest of the holes.

I had to do some fluting to get the stiffeners to lay flat. I'm not sure why they're not already flat as it's just a right angle bend to make the angle, but whatever... A little fluting fixed it right up.

Dave Hartel came by today. He's a fellow RV-7 builder in the area. He has just closed up his rudder and was nice enough to lend me the angle that he used to keep the trailing edge straight (you'll see what it's for when I get to it. Maybe tommorow...). What's neat about this is:

a) I don't have to buy angle stock (Lowe's charges about $25 for that stupid thing)

b) more importantly, it's already got all the holes drilled! Since the whole kit is CNC machined, my rudder's trailing edge should line up perfectly with those holes. We'll see.