September 30, 2005

This was my first night back at building in a LONG time. Feels good to finally be back at it! So I'm just starting on the rudder, and I had to figure out a way to cut those stupid stiffeners. My hand is NO WAY steady enough to cut them out with snips (you have to make this big, long taper). I know lots of people do it like that but I know that wouldn't work for me. I came up with this nifty little jig to do it.

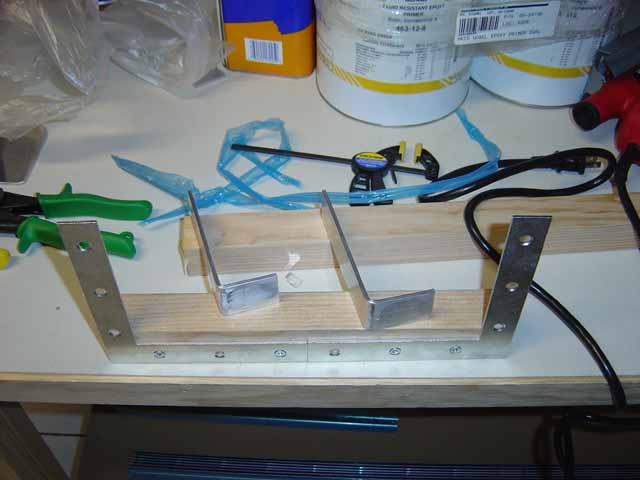

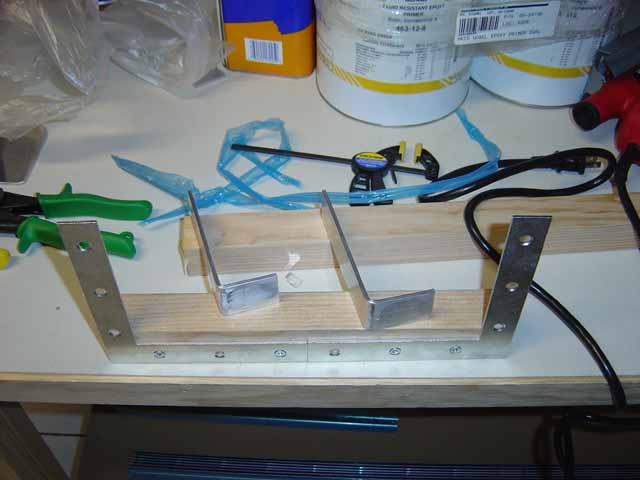

Just a block of wood with two angles on it. I made sure that the screws fit flush so I could get the stiffeners right up against them (you'll see what I mean later on). The idea is that the steal angles will act as an edge that I can use to sand the stiffeners down with my belt sander. The aluminum is much softer than the steel so no worries about grinding down the jig as well. You'll see what I do with the other two pieces of aluminum angle just lying on top of the jig. I bent those from some aluminum stock I got from Lowes. Be careful when bending the aluminum. I cracked one in half. In fact, the two you see are cracking as well, but that's OK. I wanted a TIGHT 90 degree bend. Since they don't have to be that strong, a little cracking is OK. Just don't grab them and start flexing them by hand to do a strength test. That's what I did, and YES you can break them by hand. I left the next two I made alone, and they're plenty strong for the job. No flex at al.

I drilled a couple of holes in the aluminum angle that bent so that I could cleco the stiffener to the angle. I'm holding it in my hand now, but when I marked the hole with my center punch I layed the stiffener and the angle on the jig in the same position it would be in when everything was all clamped together. This way, I would be sure that the stiffeners where right up against the jig and not flopping around.

The I used a couple of clamps to line up the cut marks on the stiffeners. The center of the cut marks are lined up with the bottom of the steal angles on the jig. Now I have a nice straight line :)

Throw it on the belt sander (I love this Ryobi belt/disc sander, by the way). On the first one, I sanded the whole thing down. On the subsequent ones I used some snips to rough cut them first (while it was clamped in the jig so I wouldn't cut too much) and then used the sander to finish it off. The first one took about 10 minutes to get right. The second one took about 5 minutes, and that includes deburring and rounding of the corners on the scotch brite wheel. 5 minutes per stiffener ain't bad. Note: The cleco in front (the lower one) will get ground down a little bit when you get close to the end of the cut. So big deal, I ruined a cleco. Oh well....

Final result is perfectly tapered stiffeners. The other side is perfectly flush as well.