November 22, 2005

Back to work!

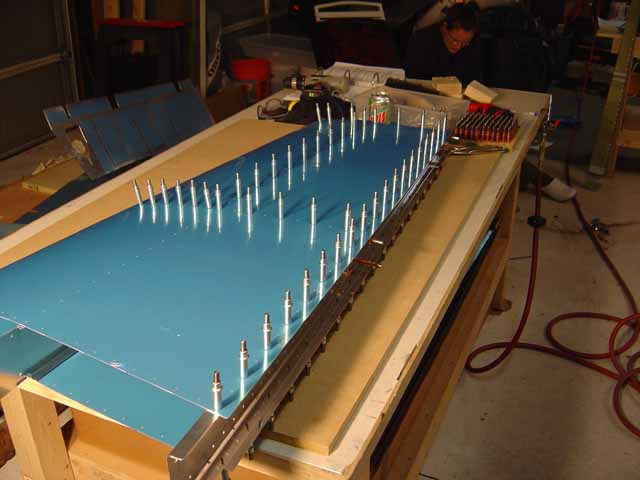

Time to start on the right side of the HS. Here I've clecoed it all together.

I didn't bother writing this up before, but there's a boo boo in how these suckers are punched, I think. The hole in the spar (on the left) is for 3/32", but the hole in the tip rib (on the right) is for 1/8". i.e. you can't really clecoe them to each other. I mean, you COULD cleoco from the rib into the spar, and it would keep it from falling apart technically, but it also lets it wobble around an awful lot. Kinda' defeats the purpose of match drilling these things, wouldn't you say? I just went ahead and drilled the spar to #30. THEN clecoed it together. Then match drilled it.

Here's Ellen helping me get the skins on the frame. Total pain in the butt. It's really easy to gouge the skins at this point. You just need to be careful, spread the skin apart wherever it's needed, and take your time.

Huzzah to the clecoer.

peasants: "HUZZAH!!"

Here's a little trick I discovered. If you ever need to a way to get a better grip on the ribs while you're positioning them, just stick a couple of clecoes in the tooling holes. Instant handles. This is the one of the root ribs. You have to mark where the rivet holes go so you can flute between them. For some strange reason, the root ribs aren't pre-punched. Now, I'm not complaining. Most of the other 8 bazzilionquagillion holes are punched, but I wonder why these were singled out. I'll worry about it in 2 years...I've got a plane to build! Tommorow, though...I'm wiped.